We have had 20 years experience!

-

Phone

00201009494489

-

Email

esdlive@yahoo.com

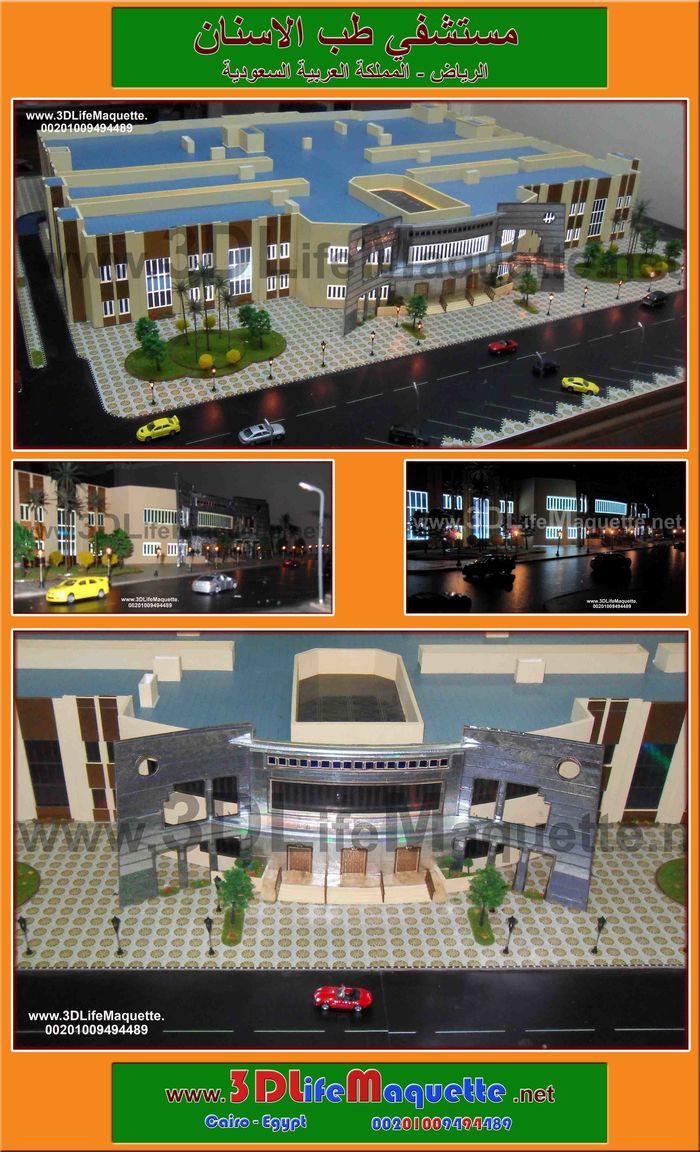

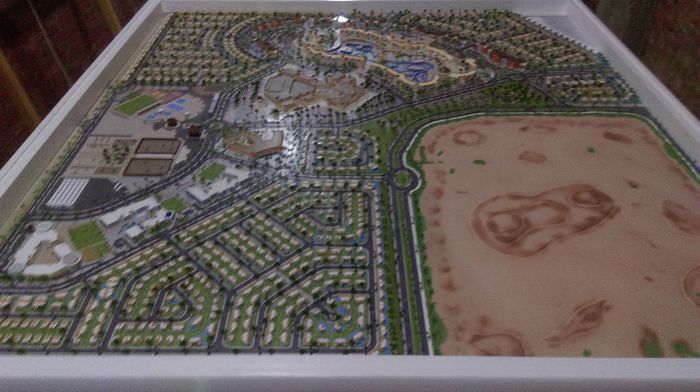

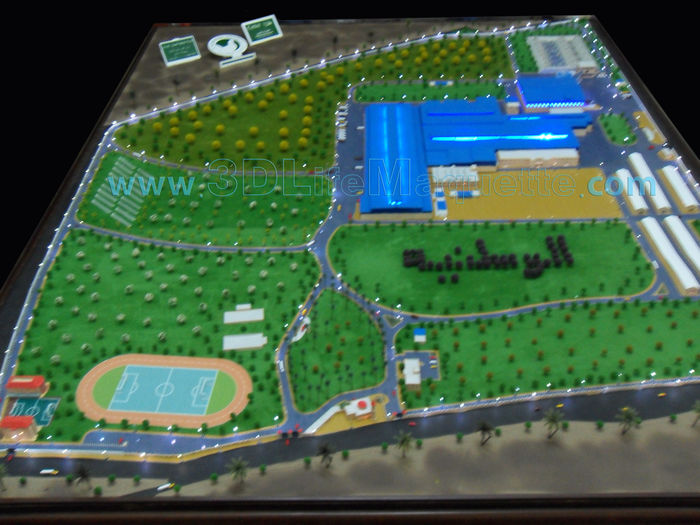

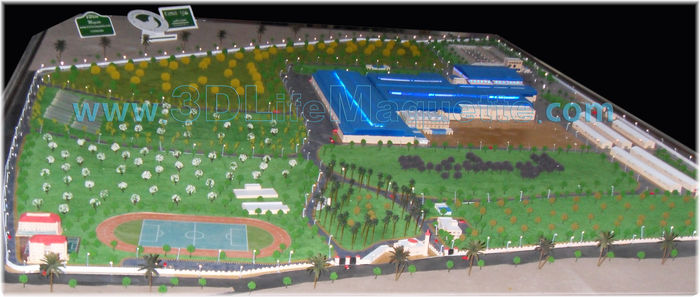

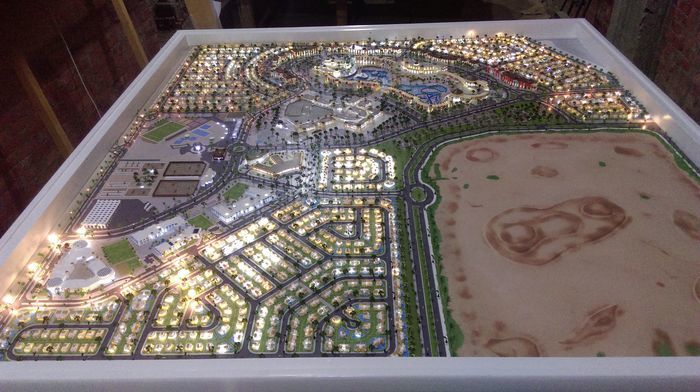

maquette

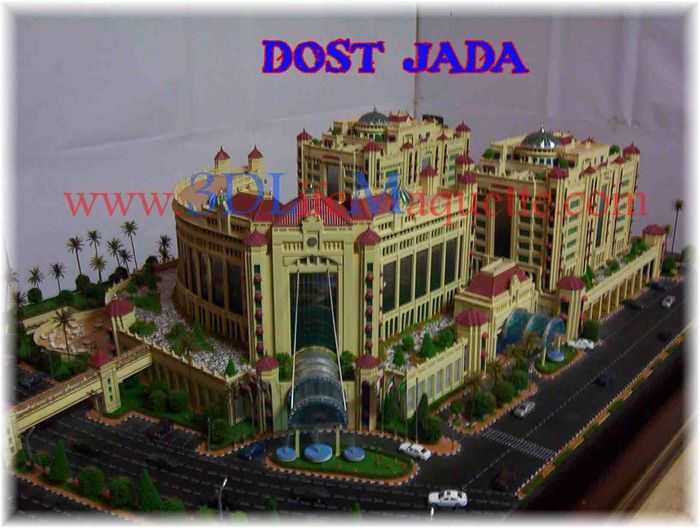

maquette (maquette) is a miniature (scale drawing) model to explain and demonstrate the idea of an architectural project

He conveyed the thought and creativity of the engineer so that the general public would understand it and help understand the design during implementation

It also appears during the implementation of the stereoscope can show and discover any design errors that are useful to the designer for modification and output at best.

In the presentation of architectural projects in offices and exhibitions for marketing and advertising Maquette used maquette

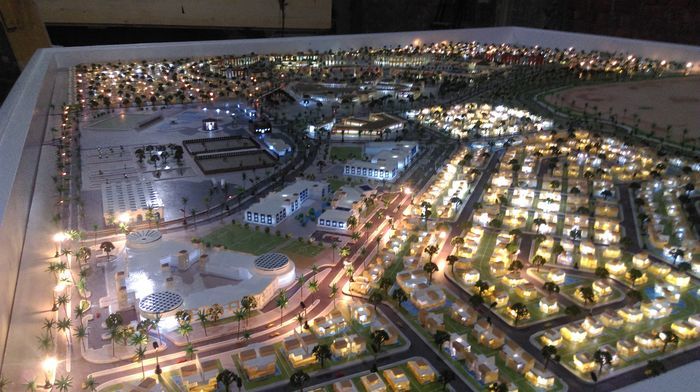

An initial study of the design can be done with initial figures during the design to help the designer avoid any design errors.

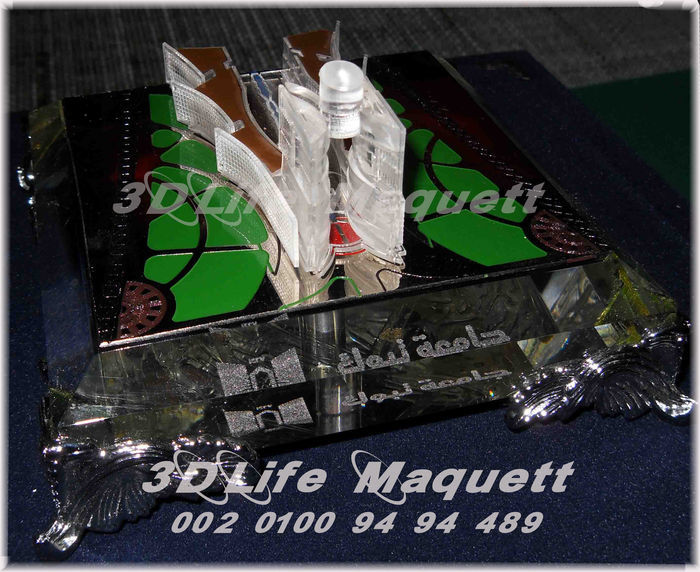

The use of laser technology in cutting, giving the finest details.

For the first time in the industry of maquette (Maquette), they developed the technique of using (porcelain) material in the implementation of maquette and complex decorative works, and we are unique in using them.

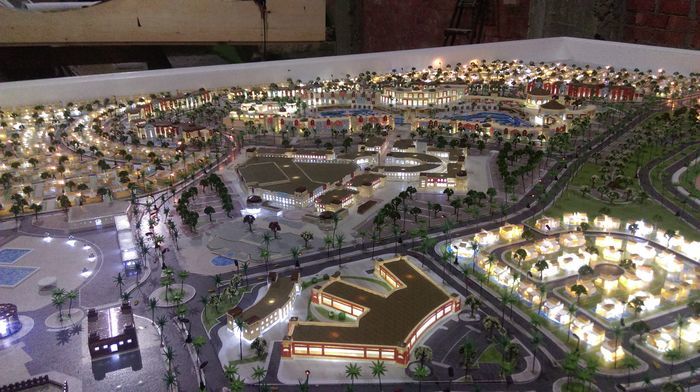

Use measured lighting for demonstration with maquette maquette laser illumination available.

Ability to add maquette mechanical movement (Maquette) with special specifications.

Newly used in maquette (Maquette). The blocks, floors and general site details are in German white plastic, with a Daco spray or a plastic (depending on the colors required). Accessories (people - vehicles - lighting poles - maquette - trees - etc ,,,) are the finest types found on the local and imported maquette market. The glass openings of maquette non-maquette mirrors are transparent according to the required color (cyan - light fam - light green) and transparent by color in the case of the maquette and maquette lighting element. Show full general site details maquette in terms of levels, maquette according to maquette, its materials and division, and general site coordination details of palm trees, trees, and crops, including maquette and maquette scale, implementation of the scale to maquette. The base of the model is made of wood or countertops according to the required design, shape, frame, alumetal and black paint. The maquette cover is made of transparent plastic, maquette (first class acrylic), thickness according to maquette, not less than 5 mm, and maquette. We cover the maquette method in one piece and it is formed in my maquette ovens. Make the special wooden crates needed to store the maquette while shipping and transporting to the show places. How it works: Using laser cutting technology to give the finest details. For the first time in the manufacture of maquette maquette (Maquette), they developed the technique of using porcelain celene in the implementation of complex maquette decorative works, and we are unique in using them. The use of thoughtful lighting in display with the availability of the maquette laser lighting with the remote control. The possibility of adding maquette mechanical movement (Maquette) with special specifications maquette. First: Consider saving a maquette. All architectural projections (plan s) for the project. All major, side and back destinations. Details details of maquette motifs, inputs and outputs for the exterior view. 3D clips are preferred for the project. Second: studying the project. maquette The study of the project and attention to all the architectural and structural details of maquette heights and depressions and the entrances and exits and inputs are studied and the work of maquette imagine the general shape of the project. Study the materials that will be used in the implementation of the main mass maquette and the quality of the material used. We assume that it is a white plastic opaque crystal maquette and take into account the thickness of the material and the maquette is appropriate to the scale of the maquette drawing that will be implemented. The windows are made of clear acrylic, 1 mm thick. The mesh shape is notched on it, and it is darkened by a sticker according to the design. Doors are made of wood (DMF) with maquette door design. Making a separation between the exterior cladding materials to paint it with a maquette color and its shape, not tolerating any small or large design, because the maquette the final display of work is based on these small. Third: Business of individuals. We take the external destinations maquette and separate each element independently to cut it from the panels of the material used and takes into account the thickness of the material used so as not to increase the length of the architectural element and maquette. After identifying all the maquette building works and they are all independent from each other with a better way to collect them, an external numbering of these maquette elements can be done so as not to make any mistakes during the assembly. Fourth: The process of cutting and assembling .. The materials are cut and they are initially plastic plates. There are two maquette methods for cutting. Initial: manual. Cutting is done by unloading the holes and making the visual effects of the walls manually using cutting and hand-cutting tools (cutter of different sizes + metal rulers + men provided instead of pen cutter ... etc) and it is required that the plastic panels be of somewhat flexible plastic for easy cutting which is of the second type Automatic cutting. Using maquette CNC machines or Laser Cat laser cutting machines. Maquette is preferred method of laser cutting because it is the best maquette, faster, and accurate in maquette cutting.

.jpg)

.jpg)